Description

Here’s what you need to know about chemical dosing systems:

Accurate Control: Chemical dosing systems deliver a controlled amount of chemicals into a liquid stream. This precise control is essential for processes like chilled water treatment, cooling tower water treatment, and general water treatment. By adding the exact amount of chemicals, you optimize performance while minimizing waste and environmental impact.

How Chemical Dosing Systems Control Odor

Chemical Injection: Specific chemicals, such as chlorine dioxide, hydrogen peroxide, or potassium permanganate, can be precisely dosed into the water to neutralize odor-causing compounds. Our systems ensure accurate and consistent injection rates to effectively manage odors.

Automated Monitoring: Our chemical dosing systems come equipped with advanced sensors and automated controls that monitor water quality parameters in real-time. This ensures that the dosing process is adjusted dynamically to address fluctuations in odor levels.

Oxidation Processes: By dosing oxidizing agents, our systems help in breaking down organic compounds responsible for foul smells. This process not only controls odors but also improves the overall water quality.

pH Adjustment: Controlling the pH level of water can significantly reduce the volatilization of odorous compounds. Our chemical dosing systems can include pH control modules to maintain optimal conditions for odor reduction.

Biofiltration Support: In some cases, supporting biofiltration processes with the right chemical additives can enhance the breakdown of odorous compounds. Our systems are designed to integrate seamlessly with biological treatment setups.

Maintenance and Safety: Regular maintenance and safety features, such as pressure relief valves and bleed valves, ensure that the chemical dosing systems operate effectively and safely, preventing over- or under-dosing that could affect odor control efficiency.

Applications of Odor Control in Various Systems

Chemical Dosing in Water Treatment Plants: Essential for managing odors in both potable water and wastewater treatment processes.

Cooling Tower Chemical Dosing: Helps in preventing odor issues associated with microbial growth in cooling towers.

HVAC Systems: Ensures that air quality is maintained by controlling odors in chilled water systems used in HVAC applications.

Parks and Gardens: Ensure a pleasant environment for visitors by controlling odors from water features, ponds, and irrigation systems.

Irrigation Areas: Maintain the quality of water used for irrigating plants, preventing unpleasant odors from affecting the surrounding environment.

Public Spaces: Enhance the overall experience in public recreational areas by ensuring that water used in fountains and other features remains odor-free.

Key Benefits

Effective Odor Neutralization: Precise chemical dosing ensures that odors are effectively neutralized.

Improved Air and Water Quality: Enhances the overall quality of water and air, contributing to a healthier environment.

Automated Adjustments: Real-time monitoring and automated adjustments improve reliability and effectiveness.

Multiple Applications: These versatile systems find use in various industries, including:

HVAC systems: Chemical dosing systems ensure proper water treatment in heating, ventilation, and air conditioning systems, preventing corrosion, scaling, and microbial growth.

Water treatment plants: Dosing systems play a vital role in municipal and industrial water treatment processes, adding disinfectants, coagulants, and other chemicals for safe and clean drinking water.

Cooling towers: In cooling towers, dosing systems precisely control chemicals that inhibit corrosion, algae growth, and scaling, promoting efficient heat transfer.

Chilled water systems: Precise chemical dosing is essential in chilled water systems to maintain optimal performance and prevent system degradation.

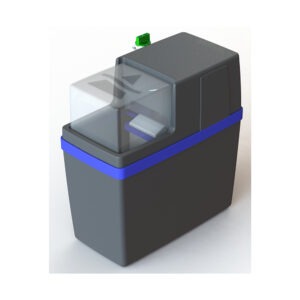

Components of a Chemical Dosing System: A typical dosing system includes:

Chemical storage tank: Constructed from chemically resistant materials like plastics or stainless steel, these tanks safely store the treatment chemicals.

Chemical metering pumps: The heart of the system, these pumps accurately measure and inject the desired amount of chemicals into the water stream.

Control valves, switches, and gauges: These components provide precise control and monitoring of the dosing process, ensuring optimal performance.

Flow meters and pressure gauges: These instruments verify the flow rate and pressure of the chemical being dosed.

Benefits of Chemical Dosing Systems:

Improved Efficiency: Precise dosing optimizes chemical usage, reducing waste and lowering costs.

Enhanced System Performance: Proper chemical treatment ensures efficient operation of water treatment plants, cooling towers, chilled water systems, and HVAC systems.

Environmental Protection: Accurate dosing minimizes the use of excess chemicals, reducing environmental impact.

By implementing a well-designed chemical dosing system, you can achieve optimal water treatment, ensure efficient operation of your systems, and contribute to a more sustainable future.

Reviews

There are no reviews yet.