SEWAGE TREATMENT PLANTS / WASTEWATER TREATMENT PLANTS

In the dynamic landscape of water treatment, few endeavors are as vital and transformative as sewage treatment plant/wastewater treatment plants. As populations burgeon and urbanization advances, the imperative for efficient sewage treatment solutions becomes increasingly urgent. At MEA Water Solutions, headquartered in the UAE, we stand at the forefront of innovation in water management. Our sewage treatment plants / wastewater treatment plants epitomize our unwavering commitment to sustainability, efficacy, and environmental stewardship.

Introduction to Wastewater Treatment Plants

Sewage treatment plants or wastewater treatment plants, also referred to as STPs, are instrumental in purifying wastewater for various applications such as gardening, agriculture, and general use. Treated sewage water undergoes purification and adheres to the strict standards set forth by regulatory bodies like the Pollution Control Board. Mandated in numerous industries, residential complexes, and commercial establishments, STPs are equipped with state-of-the-art technology and precision components to ensure optimal performance.

It’s common for individuals to conflate Sewage Treatment Plants (STPs) with Effluent Treatment Plants (ETPs). While both aim to purify water, an ETP treats wastewater before its release into the environment or for reuse. Conversely, STPs focus on removing contaminants from sewage, encompassing both domestic and industrial runoff.

Common STP Processes and Systems

Several methodologies and systems are employed in sewage treatment, each offering unique advantages:

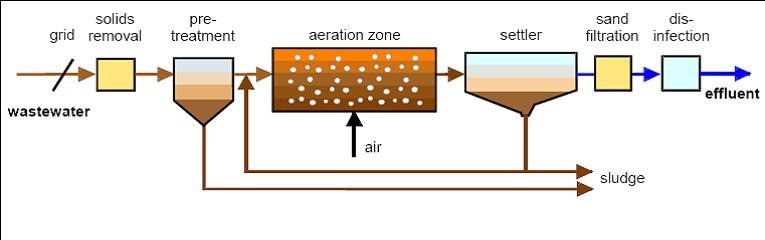

Activated Sludge Process

The activated sludge process is a biological wastewater treatment method that utilizes aeration and microbial activity to remove organic contaminants. In this process, wastewater is mixed with a microbial culture (activated sludge) in an aeration tank. Air is pumped into the tank to provide oxygen, facilitating the growth of aerobic bacteria. These bacteria metabolize and break down organic matter present in the wastewater, converting it into carbon dioxide, water, and more sludge. The mixture then undergoes settling in a clarifier, where the activated sludge settles to the bottom, leaving clarified water at the top. The Membrane Bio Reactor (MBR) represents a cutting-edge wastewater treatment technology that seamlessly integrates biological treatment with membrane filtration. This innovative approach offers a highly effective means of purifying wastewater by harnessing the natural processes of biological degradation alongside advanced membrane-based filtration techniques. The activated sludge process is widely used due to its effectiveness in removing organic pollutants and its ability to handle variations in wastewater flow and composition.

FUNCTION AND USE

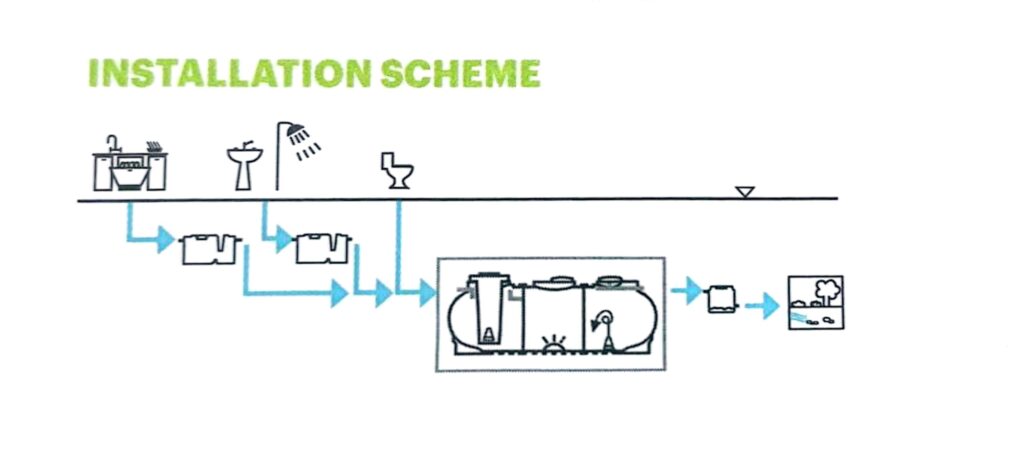

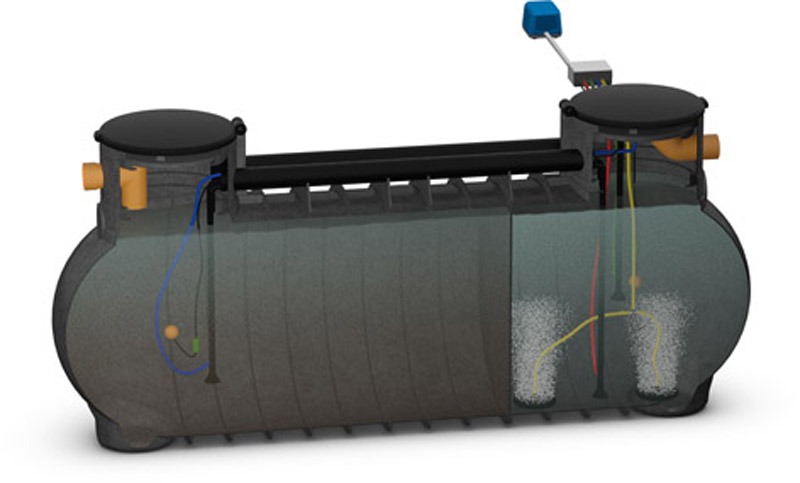

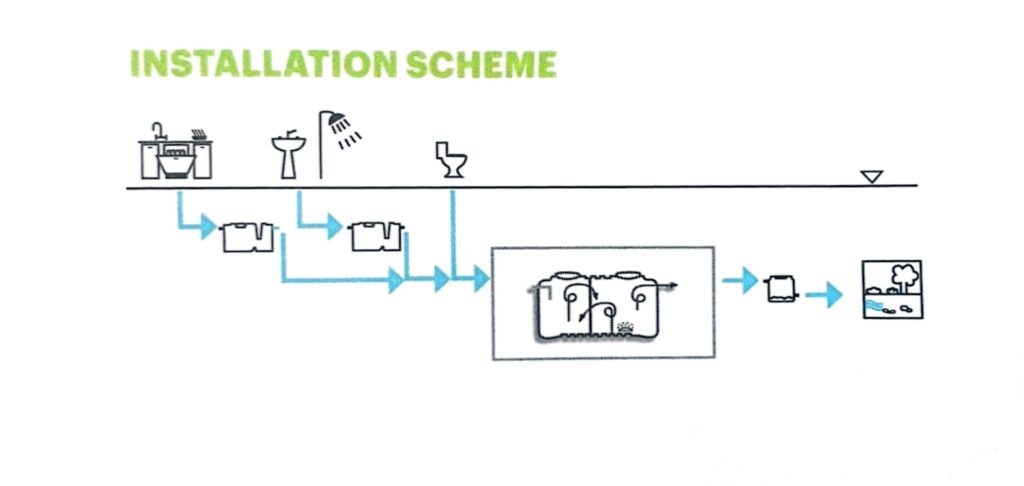

The active sludge plant with constant flow rate has the function of treating in a complete way the wastewater and is generally used on users that have punctual discharges during the day. It is made up of three compartments. The first has the function of primary sedimentation and flow equalization which allows to feed the secondary section with constant flow rate, avoiding the hydraulic charge peaks. The second is for biological treatment of the organic substances through activated sludge by air insufflation, while the third has the function of secondary settler and wastewater clarification. In the third compartment, there is generally a system for the recirculation of sludge at the top of the plant. Prior to being introduced into the system, the blonde and gray waters must be pre-treated in adequate grease separator.

Moving Bed Biofilm Reactor (MBBR)

The Moving Bed Biofilm Reactor (MBBR) is a biological wastewater treatment process that utilizes suspended biofilm carriers to support microbial growth. These carriers provide a surface area for bacteria to attach and form biofilms, where they metabolize organic matter present in the wastewater. The carriers move freely within the reactor, ensuring continuous mixing and exposure to the wastewater. This movement prevents the formation of stagnant zones and enhances treatment efficiency. MBBR systems are compact, require minimal space, and are particularly effective in treating high-strength wastewater or in retrofitting existing treatment plants to increase capacity.

FUNCTION AND USE

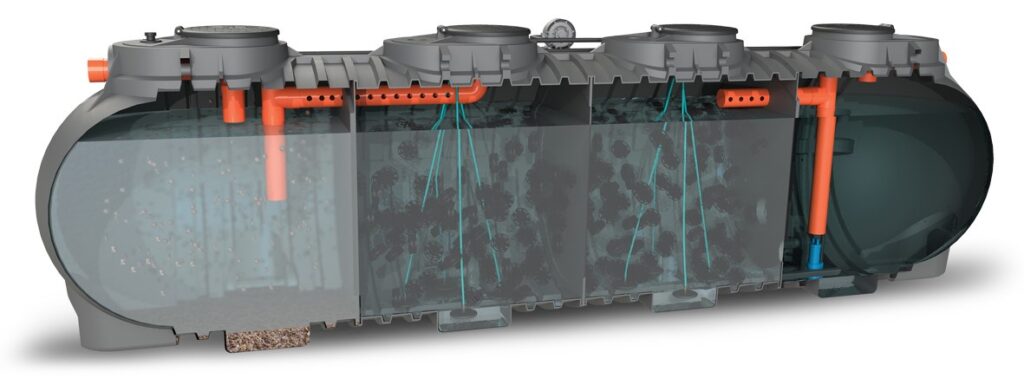

The MBBR plant is a tank that has the function of treating the wastewater in a complete way. The tank has three compartments: the first has the function of primary sedimentation, the second of biological treatment of organic substances through aerated floating bed biofiltration with bacterial flora adhered to filling bodies with a high specific surface area (carrier), while the third has the function of secondary settler. In the secondary sedimentation there is a single-phase pump for the recirculation of the sludge at the top of the plant. The blonde and gray waters must be pre-treated.

Membrane Bio Reactor (MBR)

The Membrane Bio Reactor (MBR) is an advanced wastewater treatment technology that combines biological treatment with membrane filtration. In an MBR system, wastewater is mixed with activated sludge in a bioreactor, where organic contaminants are biologically degraded by microorganisms. The treated wastewater then passes through ultrafiltration membranes, which act as a physical barrier to remove suspended solids, bacteria, and pathogens. This dual treatment process results in high-quality effluent that meets stringent regulatory standards. MBR systems offer several advantages, including compact design, reduced footprint, and superior effluent quality compared to conventional treatment methods.

Sequential Batch Reactor (SBR)

The Sequential Batch Reactor (SBR) is a variation of the activated sludge process that operates in batch mode, allowing for sequential phases of filling, aeration, settling, and decanting. In an SBR system, wastewater is introduced into a single reactor tank, where it undergoes a series of treatment cycles. During the filling phase, wastewater enters the reactor and is mixed with activated sludge. Aeration is then provided to promote microbial activity and organic matter degradation. After aeration, the mixture is allowed to settle, allowing activated sludge and solids to settle to the bottom. Finally, clarified water is decanted from the top of the tank for further treatment or discharge. SBR systems offer flexibility in operation and are well-suited for small to medium-sized treatment plants.

FUNCTION AND USE

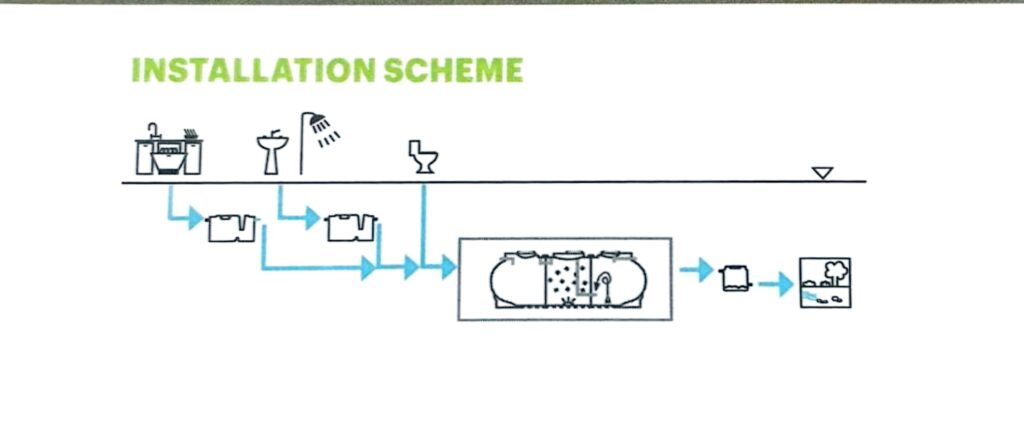

The SBR plant is a tank that has the function of completely treating the wastewater. The wastewater treatment plant must be used for incoming wastewater consisting only of domestic waste: these must be no rainwater or other types of liquid inputs. There are two compartments in the tank: the first has the function of sedimentation/equalization of the incoming wastewater, the second of biological treatment of organic substances through activated sludge and secondary sedimentation with sludge recirculation to the first compartment.

A series of air-lifts controlled in sequence by a PLC panel govern the alternating purification cycles.

Pre-treatment of blonde and gray waters is recommended.

Conclusion

In the realm of wastewater treatment, Sewage Treatment Plants or Wastewater Treatment Plants stand as bastions of environmental preservation and public health. At MEA Water Solutions, We’re dedicated to pioneering sustainable solutions that redefine wastewater management. Through cutting-edge technologies, meticulous design, and unwavering commitment, we’re shaping a cleaner, healthier future for generations to come. We provide best wastewater treatment plant and services accordingly.If you need any kind of shelving and racking support during this project Ashkal Trading can do the customizable project with high quality and satisfaction.